In today’s healthcare industry, one-size-fits-all solutions no longer meet the demands of modern medicine. The increasing complexity of medical procedures and patient needs has driven a growing demand for customizable medical devices. At Edelwise Medical Supply, we understand that customization can significantly enhance both the effectiveness of healthcare and the satisfaction of medical professionals.

1. Tailored Solutions for Unique Procedures

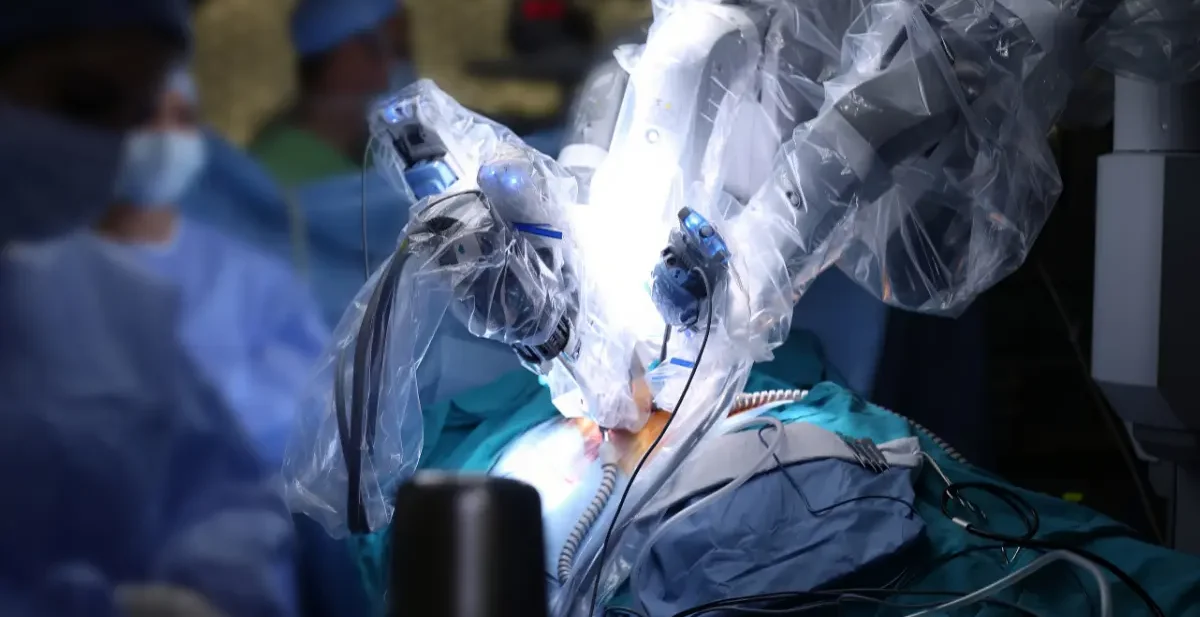

Every medical procedure is unique, and the tools used must match the specific requirements of that procedure. Standard medical devices might suffice in routine scenarios, but for specialized procedures, customization is essential.

Take, for example, our custom trocar solutions. Whether it’s adapting the blade design for a specific type of incision or offering different size options to match patient anatomy, we work closely with healthcare professionals to develop tools that meet their exact needs. This level of customization ensures that surgeons can perform procedures with greater precision and confidence.

2. Enhancing Patient Outcomes

The ability to customize medical devices also directly impacts patient outcomes. Devices that are designed to fit the specific needs of a procedure or patient can significantly reduce complications and recovery times. For example, a properly sized surgical tool or a custom-fitted suture can help minimize trauma during surgery, reducing the risk of infection and promoting faster healing.

Customization in devices like vein finders allows healthcare professionals to adjust settings to suit different skin types and conditions, ensuring more accurate vein detection and less discomfort for patients. Such improvements lead to better patient care and satisfaction.

3. Improving Workflow Efficiency

Customization isn’t just about enhancing patient care—it’s also about improving the efficiency of healthcare workflows. By providing devices tailored to the specific preferences of the medical team, healthcare providers can streamline procedures and reduce the time spent adapting to generic tools.

For example, customized handles for endomechanical instruments can improve ergonomics, reducing fatigue during lengthy procedures and enhancing surgical precision. Tailored features can help healthcare professionals work more effectively, allowing them to focus on what matters most: patient care.

4. The Future of Custom Medical Devices

As technology advances, the ability to customize medical devices will only continue to grow. Innovations like 3D printing are paving the way for truly personalized medical solutions, enabling the creation of custom-fit implants, prosthetics, and even surgical instruments.

At Edelwise Medical Supply, we are committed to staying at the forefront of this trend by continually expanding our customization capabilities. We partner with healthcare providers to understand their specific needs and develop solutions that are not only effective but also innovative.

5. Why Choose Edelwise for Customization?

Our expertise in custom medical solutions sets us apart from standard suppliers. We recognize that healthcare professionals need more than just off-the-shelf products—they need tools that are reliable, precise, and perfectly suited to their work. Our team works closely with clients to deliver exactly that, ensuring that each product meets the highest standards of quality and performance.

Whether you need a specialized surgical tool, a tailored medical adhesive, or a custom-configured trocar, Edelwise Medical Supply is your partner in providing solutions that work for you.

Conclusion

Customization is no longer a luxury in healthcare—it’s a necessity. By offering tailored medical devices, Edelwise Medical Supply empowers healthcare professionals to provide more precise, effective, and efficient care. With our commitment to innovation and quality, we ensure that every custom solution is designed to meet the unique demands of your practice.